Perfectly tuned kinematics

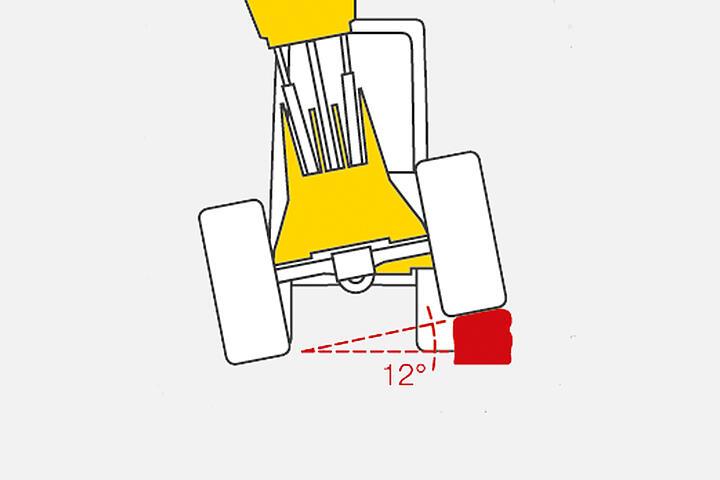

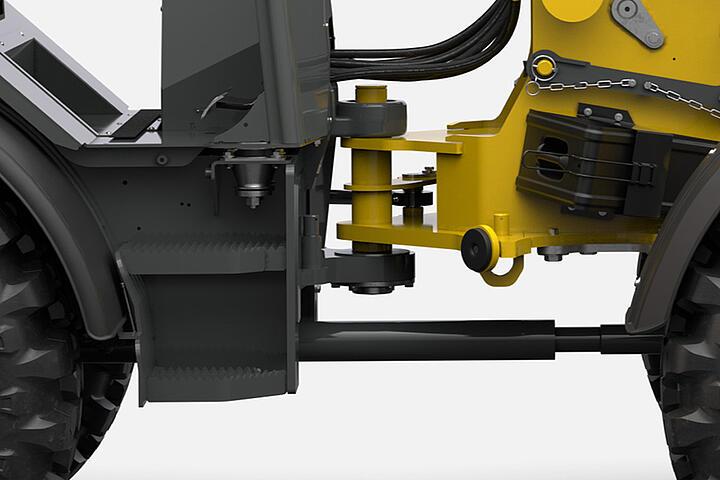

- The kinematics are adapted to the size of the machine - this ensures optimum force ratios and maximum productivity for every machine.

- The optimum coordination and processing quality of the loader arm design and hydraulic cylinders increases the longevity of the machine and thus offers added value for the customer, as working efficiency is increased.

- The theoretical maximum possible lifting capacity of the machine is always greater than the actual tipping load. The large hydraulic cylinders therefore always offer sufficient reserves and the cylinders are not operated at maximum capacity.