The milestones of Wacker Neuson

In the beginning, there was a vision. With the founding of a forge workshop in Dresden in 1848, Johann Christian Wacker laid the cornerstone for a business that continually developed for centuries and revolutionized the construction industry more than once: Wacker Neuson.

The spirit of invention and the power of innovation were formative from the beginning onward for the history of the business. In 1930, Hermann Wacker invented the world’s first electric rammer. Over 200 patents and utility models followed and found their way successfully onto the market.

2023

A strong partner for 175 years

We are celebrating our anniversary: For 175 years now, customers and their requirements have been our focus.

2022

zero emission eco system

Wacker Neuson is focusing on the entire ecosystem for customers: from charging infrastructure to services and financing offers to a lifecycle view of the battery. One example of this is the Charging Box - a powerbank for the construction site.

2020

Electric excavator EZ17e

With the electric mini-excavator EZ17e, the emission-free construction site has become reality. With it – and with the other electric machines by Wacker Neuson – an entire construction site can be operated without direct exhaust emissions and at an extremely low noise level.

2019

Dual View Dumper

Wacker Neuson puts the Dual View Dumper on the market. The wheel dumpers feature a seat and control panel you can rotate by 180°. This ensures more operator and construction site safety as well as increased flexibility.

2019

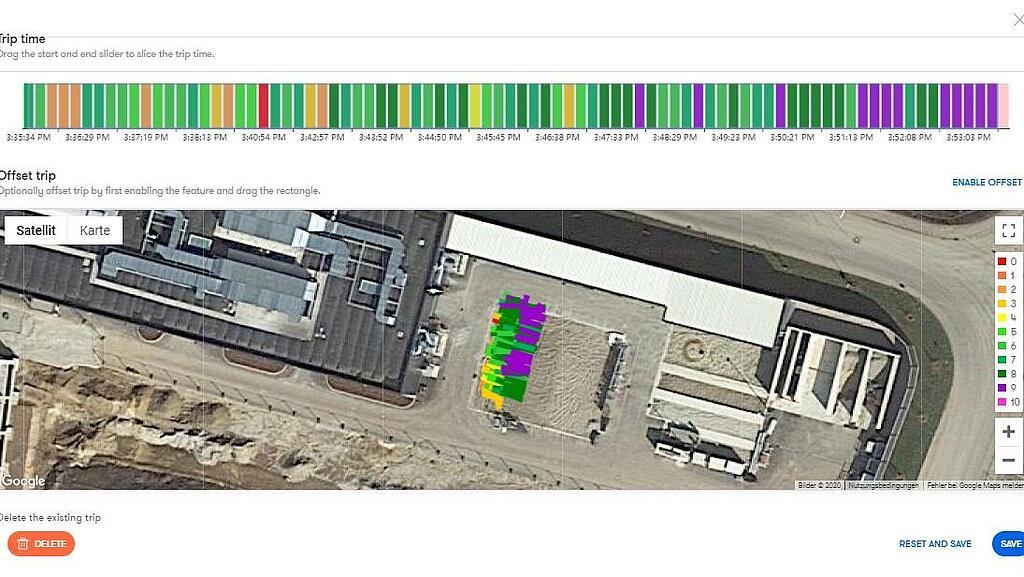

Compamatic

With Compamatic, Wacker Neuson connects Compatec, its time-tested and proven compaction control, with a telematics solution. This makes compaction progress traceable and allows for completely documented quality control – easily, from your desk.

2019

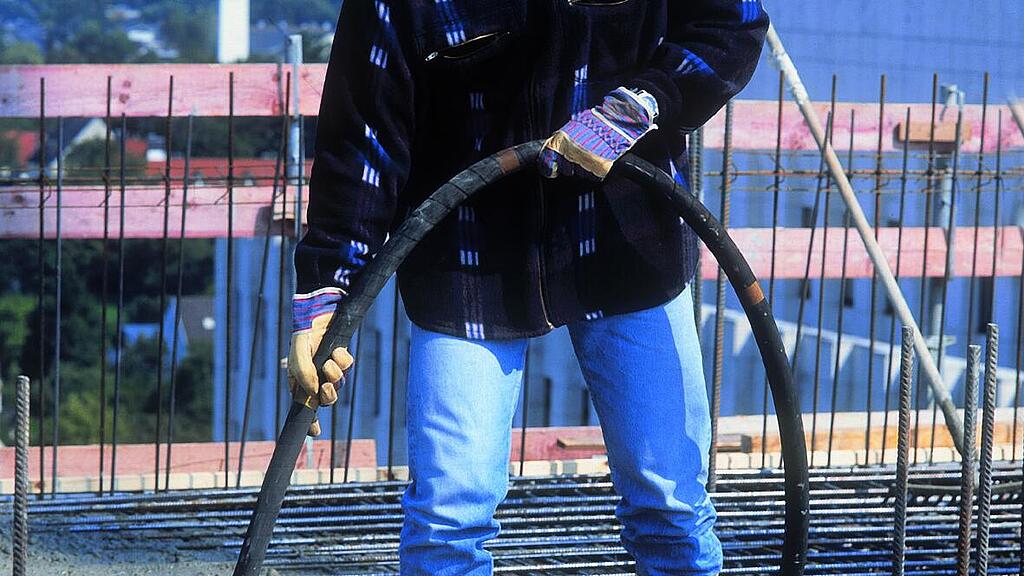

Internal vibrator with battery

Wacker Neuson puts the first battery-powered high frequency internal vibrator on the market. The battery is carried in a backpack. This makes working without a power cable possible – for more freedom of movement, more safety and operating comfort.

2019

Fully electric wheel dumper DW15e

The zero emission family gets a new member: the electric wheel dumper DW15e allows efficient material transport without direct exhaust emissions and impresses with its particularly quiet working principle, especially in sensitive environments.

2018

Battery-powered plates

Electrification keeps going. The new arrivals are the single direction vibratory plates AP1850e and AP1840e.

2014

Introduction of the zero emission series

Wacker Neuson presents its zero emission series with the electric wheel loader WL20e and the battery-powered rammers AS30e and AS50e. The mini-excavator 803 dual power is also presented in 2014. It can be operated with diesel drive or with an electro-hydraulic power unit.

2013

Compatec compaction control

The compaction control Compatec offers an orientation guide for soil compaction – especially for end users who only work with vibratory plates from time to time. Eight LED lamps indicate to the operator the relative compaction progress.

2012

New location in Linz, Austria

In 1981, with the formation of Neuson Hydraulik GmbH, the foundation stone was laid for one of the most significant product segments of the Wacker Neuson Group. Since 2012, the excavators have been developed and produced in the factory in Hörsching, near Linz in Austria.

2011

Opening of headquarters

In the north of Munich, Wacker Neuson SE’s new headquarters are inaugurated. The building is made of quality exposed concrete elements in different color tones, underscoring the company’s long years of expertise in the area of concrete technology.

2010

Most powerful vibratory plate

Birth of the DPU130r: The first vibratory plate with two base plates is launched on the market. It can replace a heavy 7-metric ton roller and is also lighter, more compact, and more flexible. The plate can be controlled with a remote control.

2007

IPO

In May of 2007, Wacker Construction Equipment AG goes public (today Wacker Neuson SE, in the S-DAX).

2007

Merger into Wacker Neuson AG

Neuson Kramer Baumaschinen AG merges with the traditional family business Wacker Construction Equipment AG. With the merger, the businesses supplement each other’s product ranges and sales regions.

2007

Quickly on the move

The Neuson 9503 is, at speeds up to 40 km/h, the fastest excavator in the world. It has established itself very quickly in the market, proving very popular with local authorities and landscape gardeners in particular.

2005

Articulated wheel loaders

Since 2005, Weidemann GmbH has been supplementing the group of companies with articulated wheel loaders. Since then, the specified compact machines have been offered under the Weidemann brand for the agricultural industry and Wacker Neuson for the construction industry.

2002

Vibratory rammer with separate lubrication

Separate lubrication eliminates premixing. This is how another milestone in vibratory rammer development was passed: perfect engine protection, maximum user-friendliness and outstanding operational reliability.

1994

Internal vibrator with integrated frequency conver

The wear-free, reliable and robust patented technology provides real benefits. Thanks to its integrated converter, the internal vibrator can be powered from a single-phase power supply. That means maximum independence on the construction site.

1991

First articulated trench roller

Under the name RT820, the first articulated universal roller is launched on the market in the early nineties. It is controlled with a remote control, can be driven in forward and reverse gears, and is exceptionally maneuverable due to its central joint.

1988

Development of VDS

An innovation in the area of excavators is the Vertical Digging System (VDS). This system allows exact vertical digging even on an uneven ground surface, curbs or slopes. This makes working more efficient, quicker and more pleasant for the operator.

1984

The first hydraulic mini-excavator

In 1984, the first Neuson Hydraulik mini-excavator came on the market. Numerous innovations followed in the mini-excavator area. As of 2000, dumpers are also developed and produced in the location in Austria.

1981

Founding of Neuson Hydraulik GmbH

In 1981, Neuson Hydraulik GmbH was founded.

1973

First reversible vibratory plate

New ideas and outstanding performance: with the first reversible vibratory plate DVU, a further milestone is achieved. Speed and both directions can be regulated variably, even permitting on the spot compaction. The operator thus has more freedom of movement and flexibility.

1964

Production plant in Reichertshofen

The Wacker business purchases a ten-hectare property for production in Reichertshofen, Upper Bavaria. In 1964, the plant is founded, to satisfy the growing demand for innovative and high-quality construction equipment for pro users.

1952

Vibratory rammer with combustion engine

New options for the application of vibratory rammers result from the incorporation of combustion engines. This way, the range and flexibility are increased. Operators can now deploy them very efficiently on construction sites without a power supply.

1934

The first internal vibrator conquers the market

As the inventor of the world’s first internal vibrator, we are revolutionizing an entire industry and making professional concrete consolidation possible. High frequency improves compaction performance and the quality of the concrete.

1930

The first electric rammer is invented

Hermann Wacker revolutionizes an entire industry. By inventing the first electric rammer in the world, he lays the cornerstone for concrete and soil compaction as well as for his company. On construction sites, work with the vibratory rammer is called “wackering”.

1848

Establishment of the Wacker forge workshop

In Dresden, the cornerstone of the company is laid. Johann Christian Wacker founds a forge workshop under the name “Wacker” in Dresden. In 1875, industrial production begins.