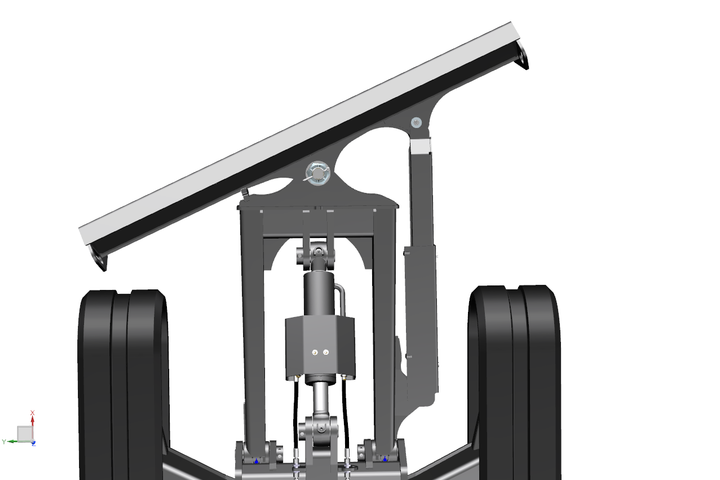

Full speed ahead: The EZ50 mini-excavator offers excellent lifting and digging power as well as quick work cycles. Using the newest technologies, the emissions of the mini-excavator were reduced and, at the same time, the efficiency increased. For example, the powerful engine in the EZ50 meets the stage 5 exhaust emission standards. In terms of operator-friendliness, the excavator is impressive. The intuitive operating concept and excellent view of the work area contribute to the easy and comfortable operation of the machine. The EZ50 is also a zero-tail excavator and is well suited for working in narrow spaces.