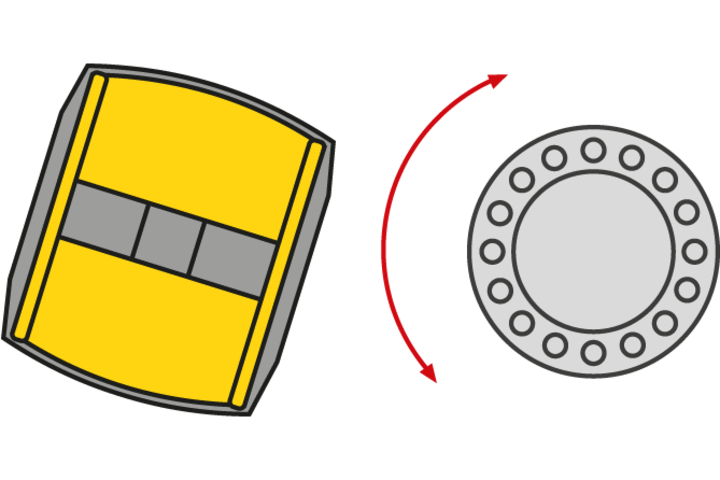

Divided base plate

- The divided base plate allows the machine to be controlled easily and precisely. Turning and maneuvering can be done without complication. This simplifies and accelerates work even in twisting and winding areas.

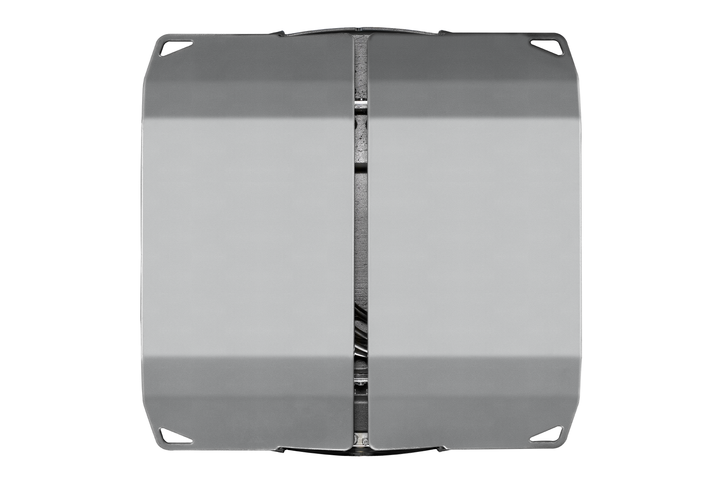

DPU130r

The DPU130r is the strongest vibratory plate on the market. With a centrifugal force of 130 kN and an operating width of 120 cm, it easily achieves the productivity of a 7-t roller – however, because of its lower acquisition and operating costs, it is much more economical. Wacker Neuson developed this remote-controlled plate for heavy-duty applications. This new design was immediately recognized with two innovation awards.